Best Modular Well Water Filtration Systems: Build Your Stack

If you're researching well water filtration systems, you already know one-size-fits-all solutions rarely deliver lasting protection. A truly good home water filter for well water must adapt to your unique contaminants while fitting seamlessly into your daily life. After years testing these systems, I've learned certified performance only matters if you'll actually maintain it, and that starts with a modular design that reduces friction. Let me show you how to build a stack that protects your family without becoming a chore.

Why Modular Beats Monolithic for Well Water

Well water challenges are intensely personal. Iron, sulfur, bacteria, or sediment levels vary wildly even between neighboring properties. A rigid, single-unit system often fails when contaminants shift seasonally or as your well ages. Learn how seasonal water quality changes can alter contaminant levels and certification needs so your stack adapts year-round. Modular systems solve this by letting you add, remove, or resequence stages based on actual test results, not marketing claims.

The Maintenance Reality Check

I once spent 40 minutes wedged under a sink with a swollen wrist, cursing a cartridge that required two wrenches and a contortionist's flexibility. That's why I now prioritize tool-less housings, quarter-turn mounts, and clearance checklists in every review. If changing filters feels like punishment, families skip it, and certified protection vanishes. If it is hard to maintain, it will not protect you.

Key Advantages of Modular Setups

- Future-Proofing: Start with iron/sediment removal, then add UV for bacteria if tests show coliforms later.

- Cost Control: Only replace exhausted stages (e.g., swap carbon but keep the mineral tank).

- Flow Rate Preservation: Bypass unused stages to avoid pressure drops (critical for 3+ bathroom homes).

- Renter-Ready: Temporary setups with NSF-certified bypass valves for lease restrictions.

Pro Tip: Always request a pre-installation flow test. Many systems promise 15 GPM but crumble at 8 GPM under real pressure. Your shower's comfort depends on this metric.

Your Modular System FAQ: Answered Without Hype

Q: How do I know which modules I actually need?

A: Skip the guesswork. First, get a comprehensive well test ($150-$300) from a state-certified lab (not a free "marketing" kit). Focus on:

- Iron >0.3 ppm -> Requires oxidation stage

- Sulfur smell (rotten eggs) -> Needs catalytic carbon after oxidation

- Coliform bacteria -> Mandatory UV purification

- Low pH (<6.5) -> Calcite neutralizer before iron removal

Example: The SpringWell WS1 system uses air injection for iron/sulfur before carbon filtration. But if your tests show only sediment, skip oxidation and use a basic sediment pre-filter stack (saving you $400 and maintenance steps).

Q: Won't adding modules reduce water pressure?

A: Not if you design smartly. Follow these preflight steps:

- Measure inlet pressure (ideal: 40-60 PSI). Below 35 PSI? Add a booster pump before filtration.

- Calculate total GPM needs: Add 2.5 GPM per bathroom + 1.5 GPM for kitchen/hose spigots. A 3-bath home needs 10+ GPM.

- Sequence modules by flow impact: Place high-flow sediment filters first, low-flow UV last.

Systems like the Home Master HMF3SdgFeC use 20" filters for 15 GPM flow, proving size and sequence matter. Flow rate metrics aren't just specs; they're usability guarantees.

Q: How do I avoid maintenance friction with modular systems?

A: Prioritize these often-ignored features:

- Tool-less cartridge swaps: Look for quarter-turn housings (e.g., 3M Aqua-Pure AP903's Sanitary Quick Change design).

- Visual life indicators: Clear sumps showing carbon saturation (no guessing games).

- Standard fittings: 1" NPT threads mean any plumber can service it, not just the brand's "special" tools.

Q: Are add-on filtration modules worth the extra cost?

A: Only when they solve your specific problem. Let's compare real costs:

| Module Type | Use Case | Avg. Yearly Cost | Maintenance Burden |

|---|---|---|---|

| Hydrogen Peroxide Injector | High sulfur/bacteria | $250-$600 | Add chemical monthly; safety cautions noted |

| UV Purifier | Bacterial contamination | $120 (bulb) | Annual bulb change; no tool friction |

| Calcite Neutralizer | Low pH water | $80 (media) | Media refill every 6-18 months |

The US Water Systems Matrixx uses peroxide injection for sulfur, powerful but high-maintenance. For most homes, air-injection + carbon (like SpringWell WS1) offers simpler maintenance with certified results. Always match the module to your lab report, not worst-case scenarios.

Q: How do I make this system actually last?

A: Build a maintenance rhythm, not a chore. My 3-step checklist:

- Anchor to existing habits: Change filters when you switch smoke detector batteries (spring/fall).

- Use gallon counters: Skip "every 6 months" myths; replace when actual use hits capacity (e.g., Pentair PC600's 650k-gallon rating).

- Verify performance: Post-replacement, run a $20 chlorine test strip. If it's blue, your carbon stage works.

Safety note: Never bypass UV during maintenance. Temporary bottled water use beats risking contamination.

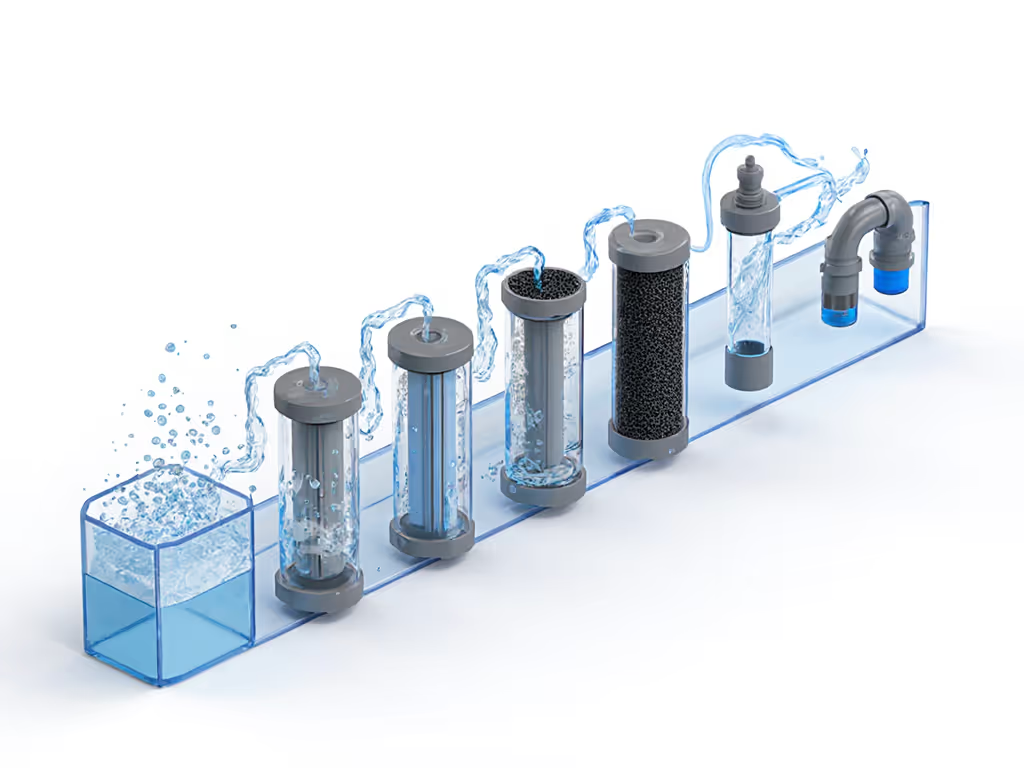

Building Your Stack: A Step-by-Step Flow

Follow this sequence to avoid costly mistakes:

- Start with sediment: 5-micron pre-filter (e.g., inline spin-down) to protect downline stages. Replace every 3-6 months. See our sediment pre-filter comparison to pick the right micron rating, media, and flow rate for your well.

- Address oxidizable contaminants: Iron/sulfur need before carbon. Air-injection (no chemicals) vs. peroxide, choose based on lab results.

- Add adsorption: Catalytic carbon removes residual sulfur/iron and breaks down oxidizers safely.

- Finish with purification: UV for bacteria, RO for nitrates (only if needed!). If microbes are a concern, review the UV purifier science before you size a unit.

Critical Design Checks

- Clearance: Measure cabinet space before buying. Need 6" clearance around housings for tool-less swaps.

- Flow Path: Avoid 90-degree elbows near filters, they strangle flow. Use sweeping bends.

- Drain Access: UV/pump stages need nearby floor drain (or bucket during service).

The Bottom Line: Protection That Fits Your Life

A modular well water filter system isn't about complexity; it's about intentionality. By matching stages to your water and your routine, you turn maintenance from a dreaded chore into a 10-minute ritual. That's how certified performance becomes real protection.

Remember: If it is hard to maintain, it will not protect you. Choose systems that respect your time as much as your health.